-

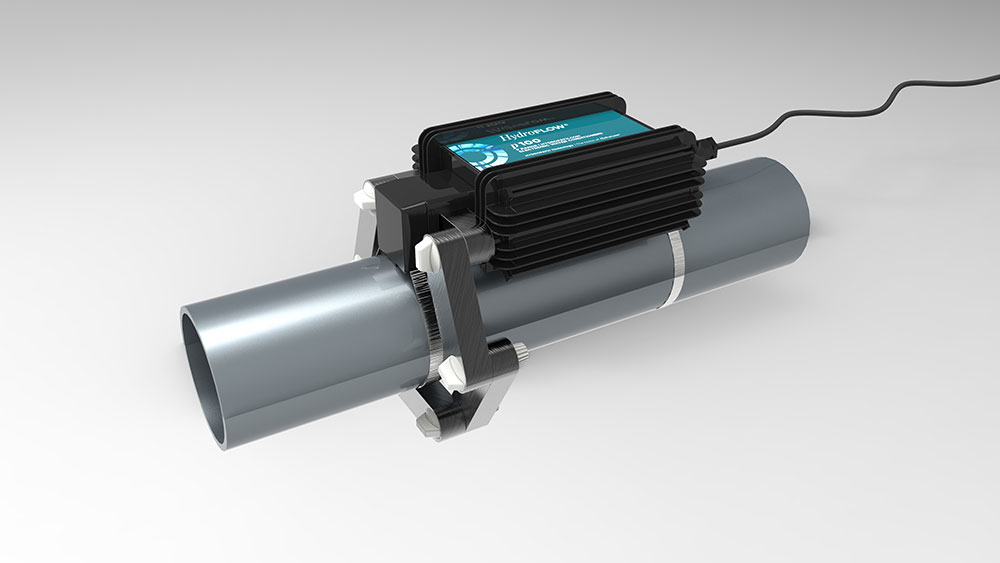

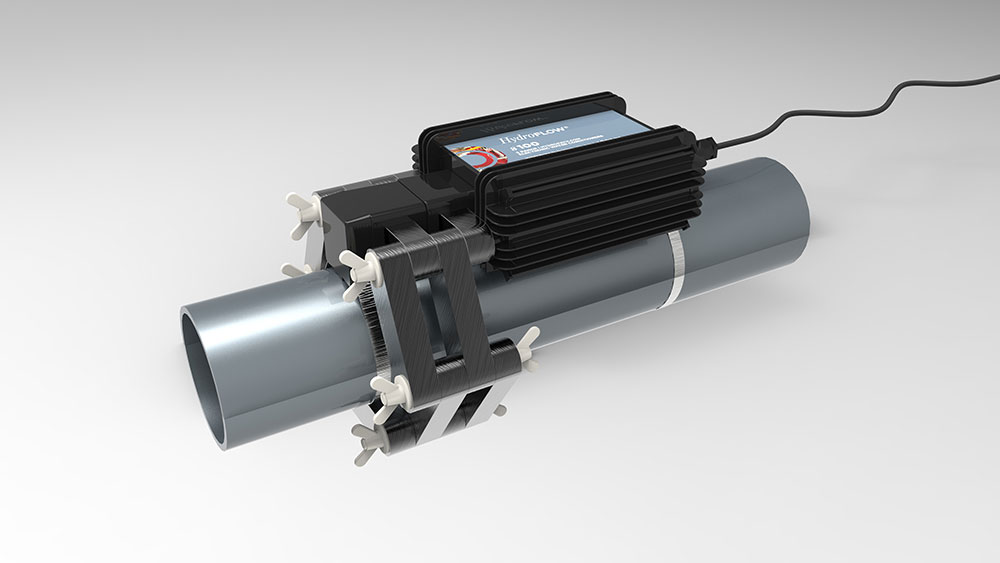

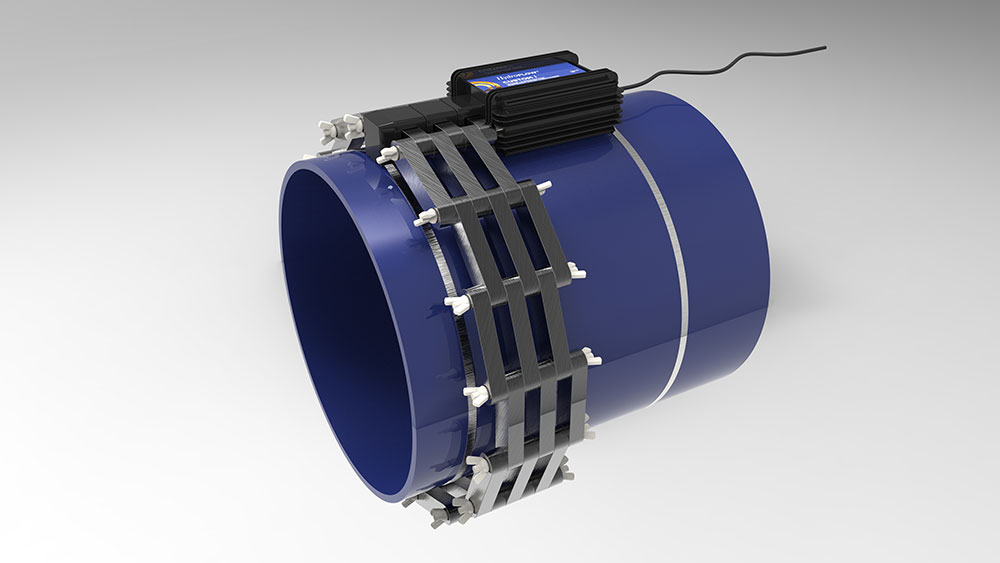

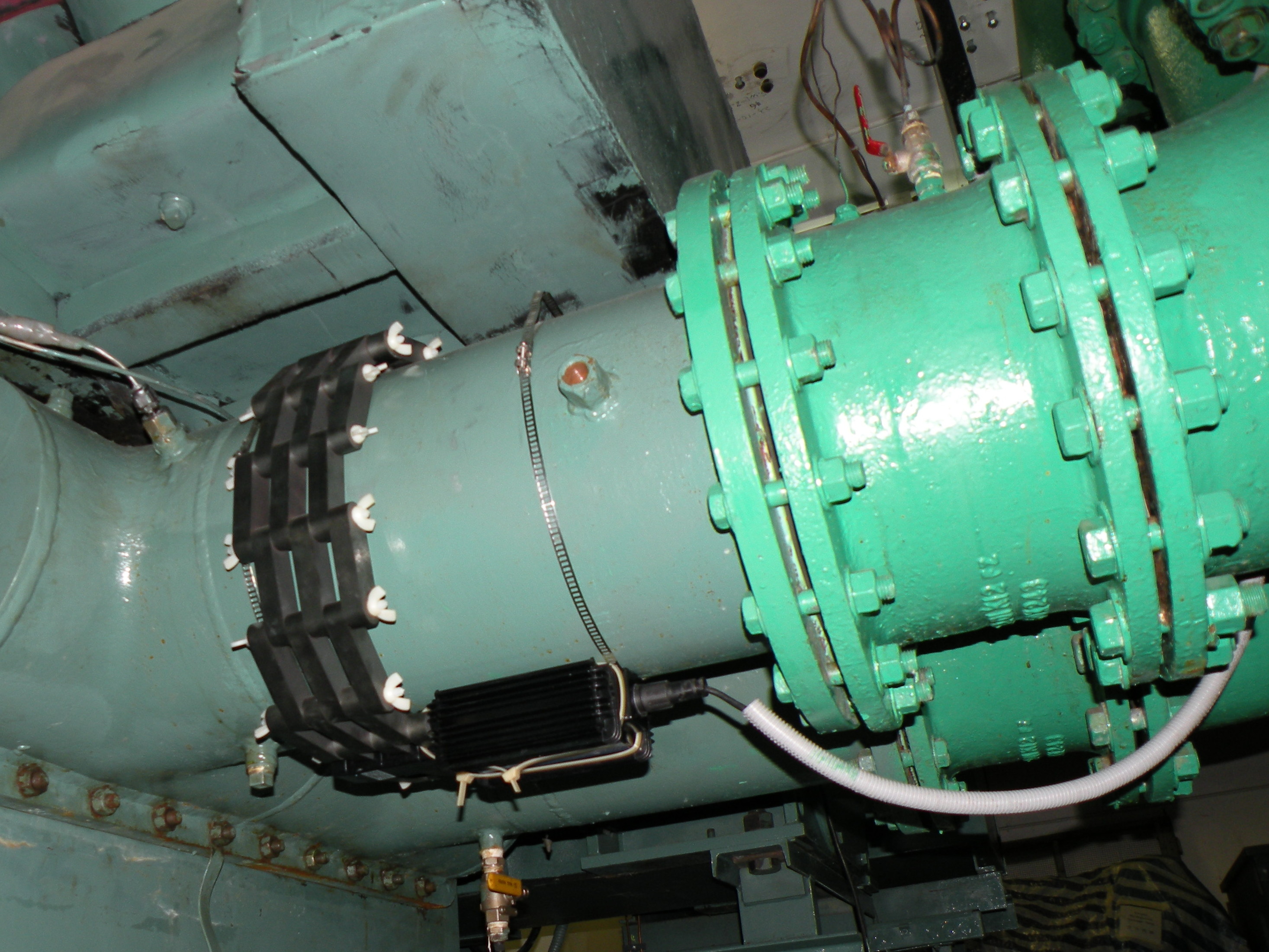

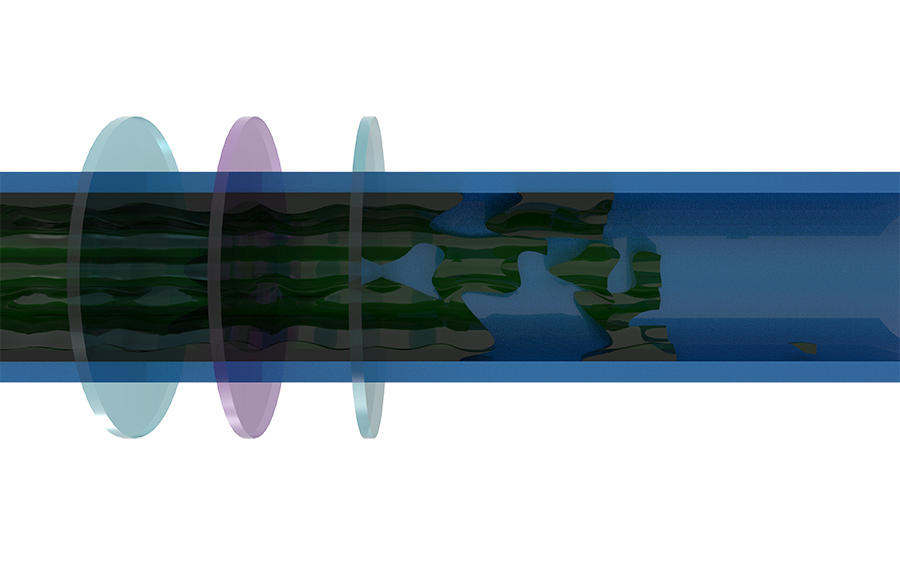

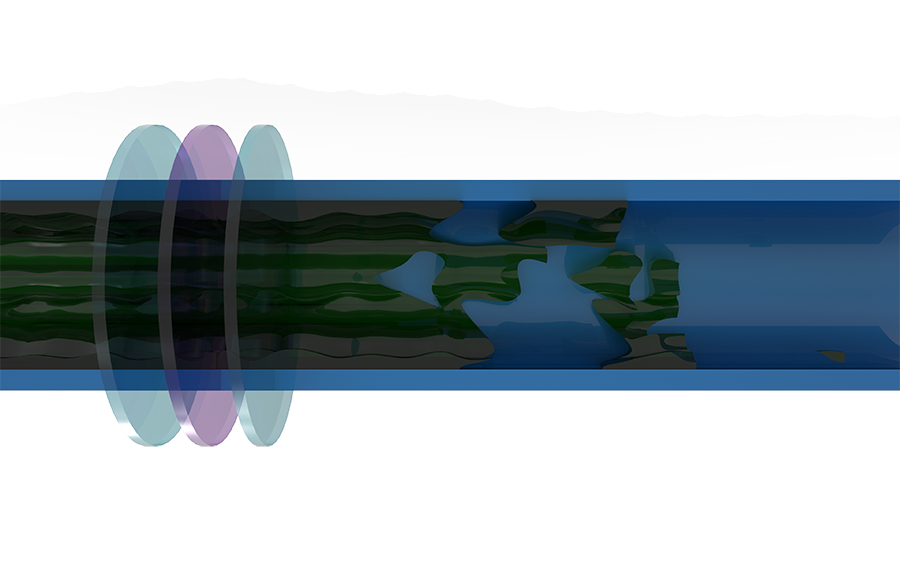

HydroFLOW® Electronic Water Conditioners

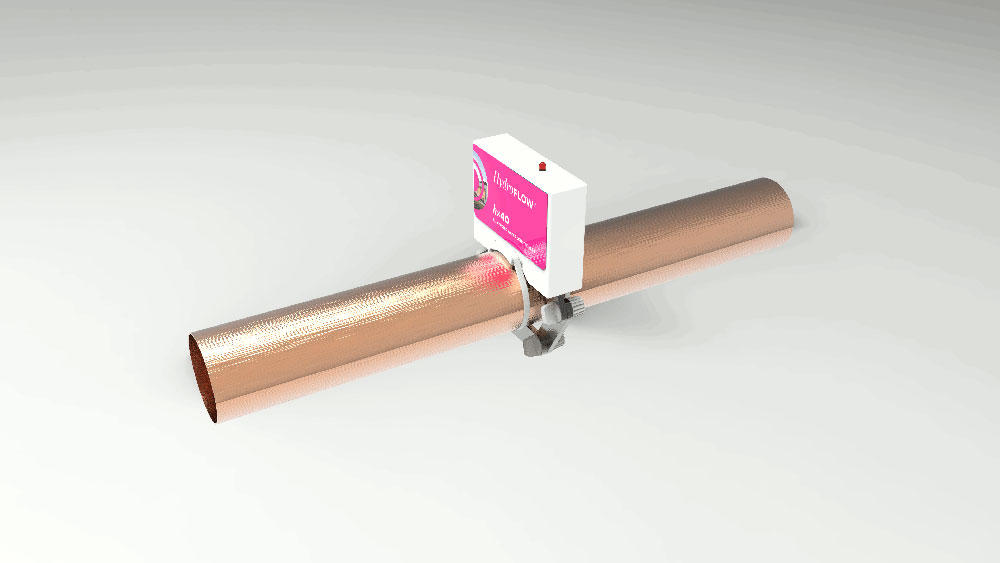

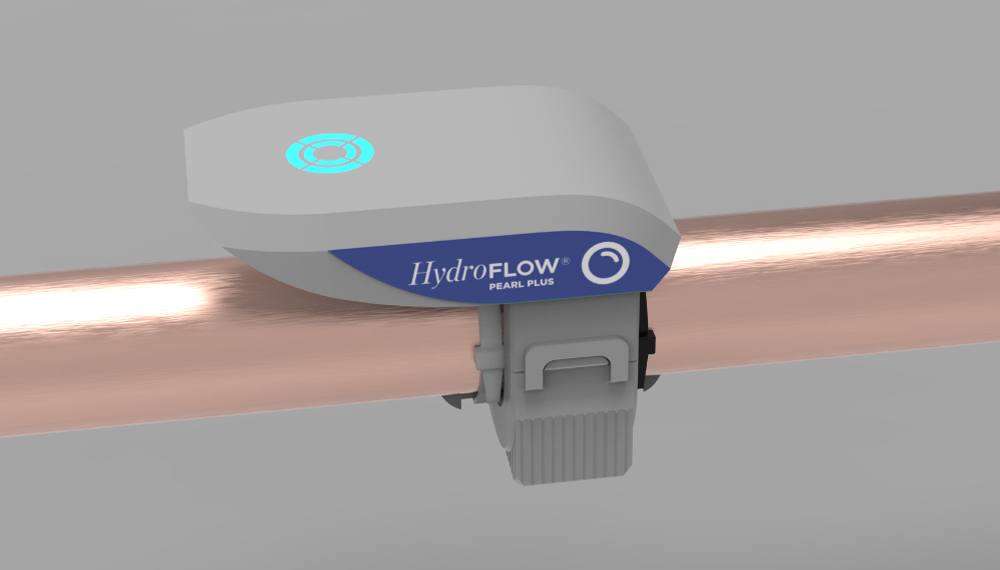

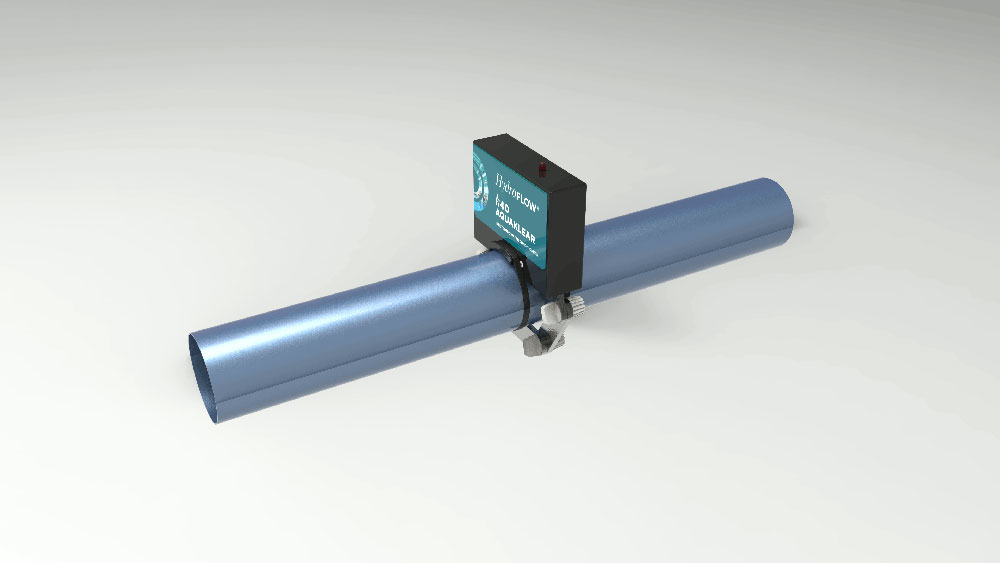

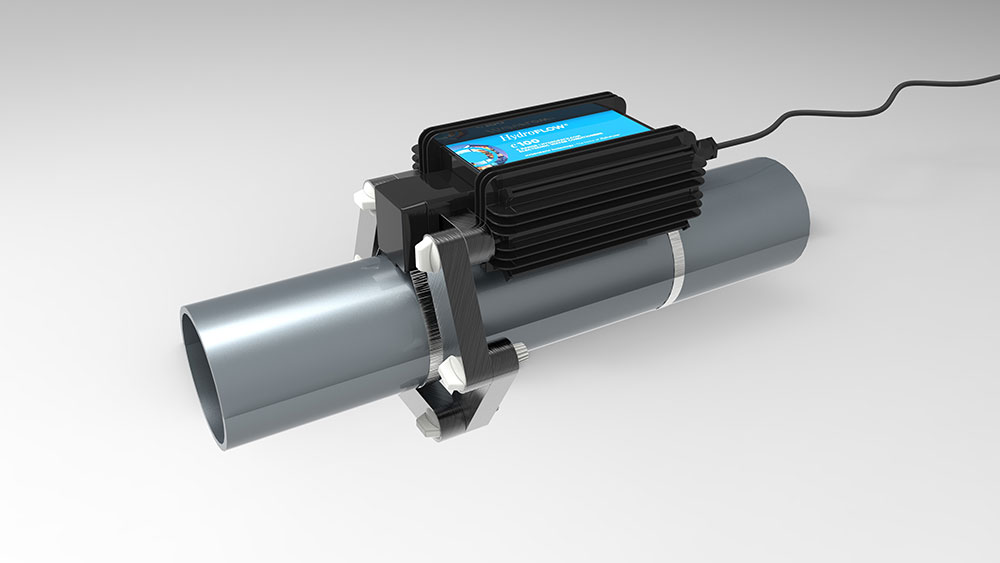

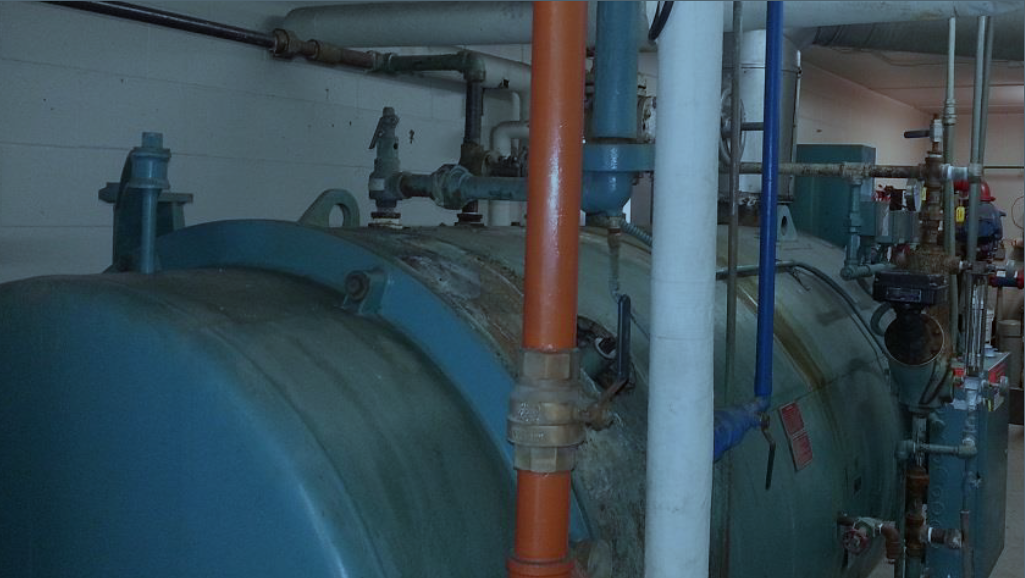

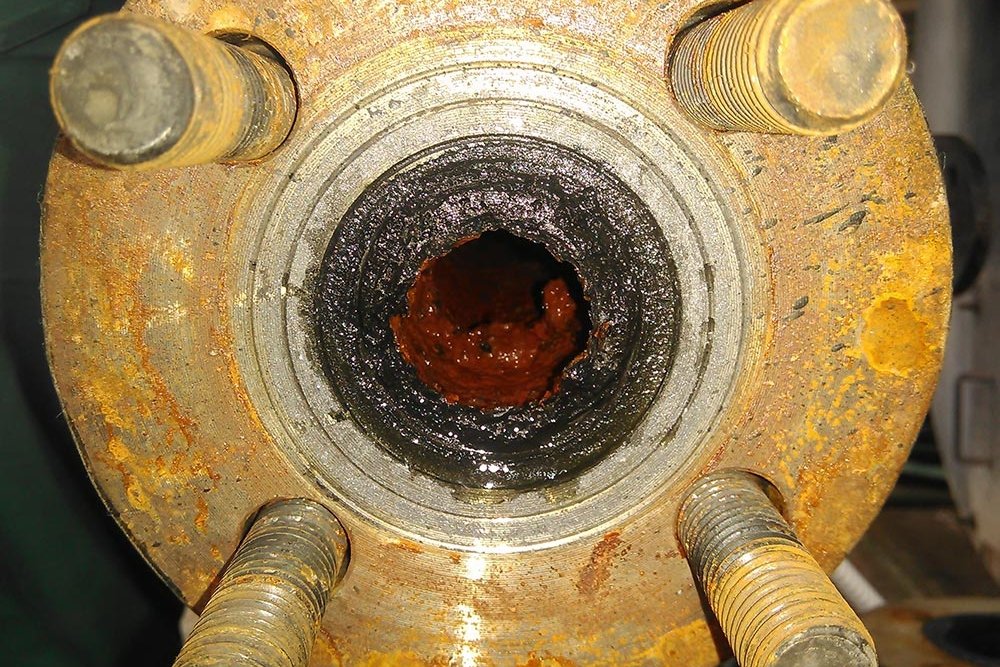

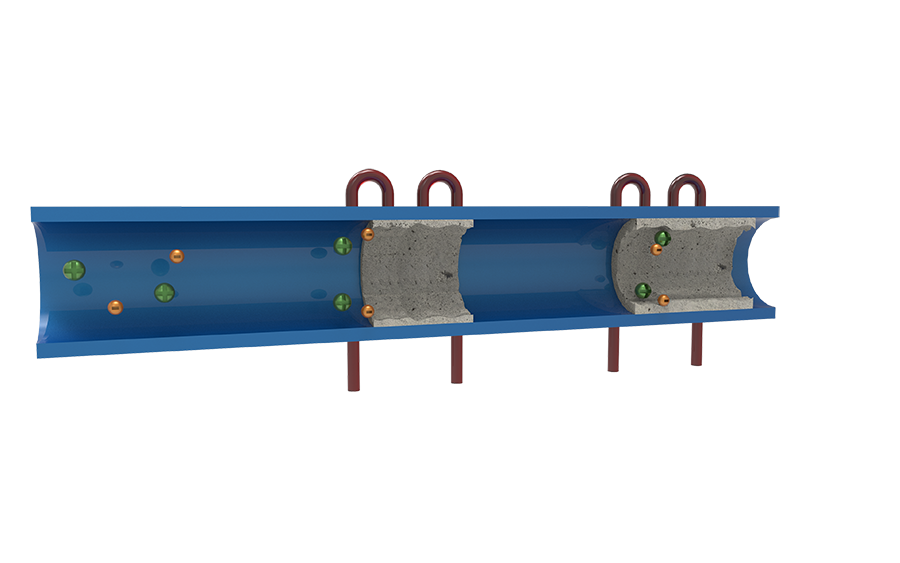

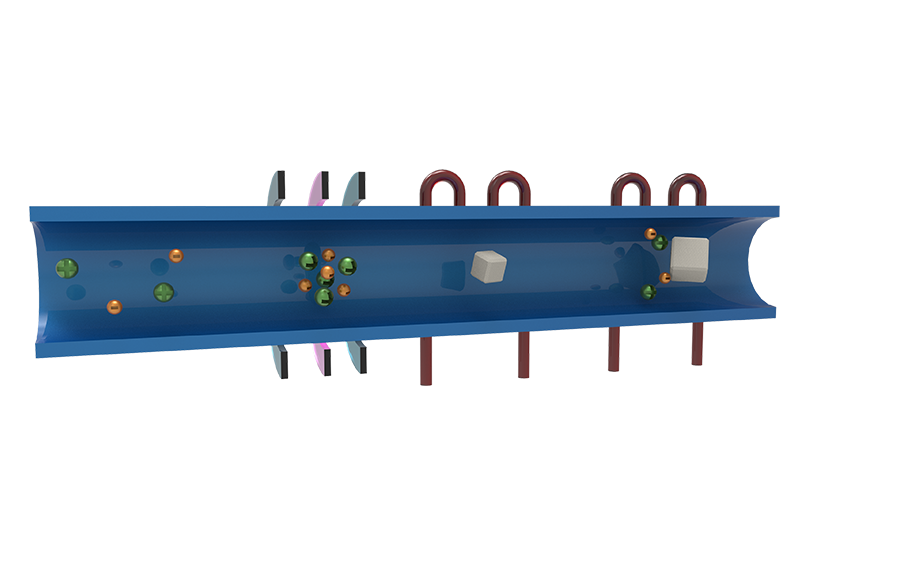

HydroFLOW® Electronic Water ConditionersHydroFLOW® water conditioners provide the ultimate in water care technology to global business, industry and consumers – reducing limescale, preventing bio-fouling, enhancing filtration and offering chemical-free solutions with a difference.

-

HydroFLOW® Electronic Water Conditioners

HydroFLOW® Electronic Water ConditionersHydroFLOW® water conditioners provide the ultimate in water care technology to global business, industry and consumers – reducing limescale, preventing bio-fouling, enhancing filtration and offering chemical-free solutions with a difference.